Reddit reviews Concrete Countertops: Design, Forms, and Finishes for the New Kitchen and Bath

Reddit reviews Concrete Countertops: Design, Forms, and Finishes for the New Kitchen and Bath

We found 3 Reddit comments about Concrete Countertops: Design, Forms, and Finishes for the New Kitchen and Bath. Here are the top ones, ranked by their Reddit score.

Used Book in Good Condition

are you talking about placing the granite in a mold and then pouring concrete to fill up the rest of the mold?

if that's the case, i would place the granite in the mold so that the polished side is exposed when the counter top is taken out of the mold.

http://www.toolocity.com/5-jx-shine-wet-diamond-polishing-pads.aspx

click that link and you will find the pads you will need to polish the counter top. read the description "For granite and concrete."

for tops poured upside down in molds, i line the molds with a smooth formica type product and normally start polishing with a 400 grit pad. this will initially dull the polished granite but as you increase the grit, you will eventually get it close to back to the smoothness it is now.

I have done concrete counters and finished them at 3000 grit. it's glassy smooth but not as shiny as polished granite which i believe is finished all the way up to 8500 grit. i have 6000 and 8500 pads but have never used them. you could in theory just polish the whole top to 8500. the problem there is going to be that the concrete will not have enough 'tooth' to accept a topical protectant but their are solutions that soak in to protect. i have never used a protectant, i just keep them coated with mineral oil and let the chips fall. i like the patina. just be careful not to get lemon or lime juice on the concrete. fugly white stains that take forever to leach out. wine is somewhat of a problem but leaches out fairly quickly.

read up on the polishing process. it's messy as hell as you have to keep the pads wet. if what i have interpreted your project to be, it's totally doable and i think it would be an interesting outcome. whatever you do, pour a practice piece first and get the polishing process down before you start on a counter top sized piece. good luck.

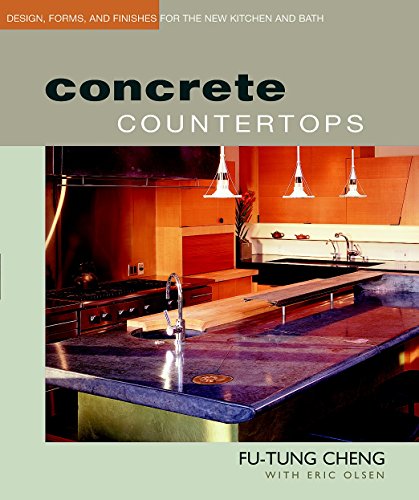

http://www.amazon.com/Concrete-Countertops-Fu-Tung-Cheng/dp/1561584843

get ahold of that book somehow and it will answer a lot of your questions.

So as promised here are the majority of materials/tools I used to make the counters. I used the stain instead of actually coloring the concrete as I was worried about getting inconsistent coloring since I was doing multiple batches.

Now, my mistake I made which turned ok after the fact was that the concrete became too dense for the stain to penetrate. Despite using the sawzall to try and vibrate the air bubbles out from the bottom of the concrete but I was not able to get all of them out so there was pin holes on some of the counters. So I made a slurry as recommended and filled in all the holes and then sanded the high spots down. So when I stained the counters the areas that had been filled with slurry took to the stain very well but the actual concrete only became a darker grey. I communicated with a staff from ConcreteSolutions and they were very helpful in trying to get the stain to penetrate the concrete. I stained it probably 3 times and then just left it as it was and now I really love how it turned out despite not being as planned. Its almost like a black and grey leopard spot on most of the counters, the island area was the last poured and had hardly any air bubbles so its more solid color…

I let them sit and harden at least a week before I flipped them over and started sanding away. I did not want a exposed aggregate look so I had to be careful about sanding too much…

The stain and sealer work great and like the other user said, liquid just sits on an it and doesn’t not penetrate.

If you have any questions ask away- I had lots of friendly people help me on other forums and was very thankful for their help….

Chengs Book

http://www.amazon.com/dp/1561584843/ref=pe_385040_30332190_TE_3p_dp_1

Sealer

http://concretecountertopsolutions.com/products/sealers-and-polish/z-siacryl-14-sealer/

Polish

http://concretecountertopsolutions.com/products/sealers-and-polish/z-counter-shine-polish/

Dye/Stain

http://concretecountertopsolutions.com/products/stains-and-integral-colors/z-aqua-tint-dye/

Nylon Fibers

http://www.amazon.com/gp/product/B000COCDCM

SUPERPLASTICIZER

http://www.ebay.com/itm/-/161011304020

Diamond polishing pads

http://www.amazon.com/gp/product/B00AB1UMOW

Variable speed polisher

http://www.harborfreight.com/power-tools/polishers/7-in-10-amp-variable-speed-polisher-60626.html

There are two primary ways of doing it: cast in place, and molded. For a desktop you probably want to make a mold and drop the top onto the desk. If the existing surface has weird crap all over it, (like a messed up wood surface,) you might cast in place instead of seating on top of it. In any case, you have to be careful doing anything less than about 1.5" thick. I use rebar in the concrete, but in thin pieces you have to use hardware cloth (metal,) chicken wire, or expanded metal mesh. I use "remesh," a very widely spaced, square mesh.

To make a mold, you'd use melamine (plastic) coated MDF board. You need to work on a flat, level surface that you can bang on. You need black silicone caulk to seal the seams of the mold.

The process is a fair amount to explain in a reddit comment; I highly recommend the book by Fu-Tung Cheng as well as his video. (I can send you a DVD if you want.)

In a mold, the bottom is the top, so you could round the corners by putting a heavy bead of silicone caulk and smoodging it (technical term) into a nice, rounded profile. If pouring the top in-place, you could pull the side pieces off early (before the cement is fully hard) and pull something like a plastic bag down the edge, rounding it over.

There are many points to cover in the process of pouring concrete, but one that's often overlooked is your floor. Some large, 2" thick counter tops my gf & I made weighed about 450 lbs when finished. Make sure your floor can handle that. (and your desk!)

So... Mold: melamine board on the bottom, melamine strips for the sides, held with screws (pre-drill holes!) or corner brackets. The bottom (against the melamine) will be your top. Silicone seal all seams, or water seeps out. That's bad. Concrete needs moisture to cure, and your corners will be all dry and crumbly. Pour in place: Like a mold using your desk as the bottom. The top surface will be your top, so you can trowel or diamond-sand as you like.

Either way, you should also agitate the wet concrete. It settles it and causes air bubbles to rise to the surface. That can be as simple as banging on it with a hammer/mallet or lifting the whole work surface with a lever & dropping it back down. (Must have a solid floor for the lever approach.)

I recommend using Quickrete 5000 high early strength. Cures faster than regular concrete. Cures to full hardness in 28 days, usable in ~2 days.

So... I've probably raised more questions for you than I've answered. One good thing to do is to buy a bag or two (it's cheap--~$5/bag) and do some small practice molds. Even in buckets. Get the feel for troweling and sanding.

I also recommend Cheng's concrete sealer. It isn't cheap, but it's worth it. I use inexpensive Quickrete pigments for color.

I'm happy to answer questions, and seriously, if you want the Cheng DVD, just PM me an address. It's full of great info.