Reddit reviews Dap 00271 Weldwood Original Contact Cement, 1-Pint

Reddit reviews Dap 00271 Weldwood Original Contact Cement, 1-Pint

We found 4 Reddit comments about Dap 00271 Weldwood Original Contact Cement, 1-Pint. Here are the top ones, ranked by their Reddit score.

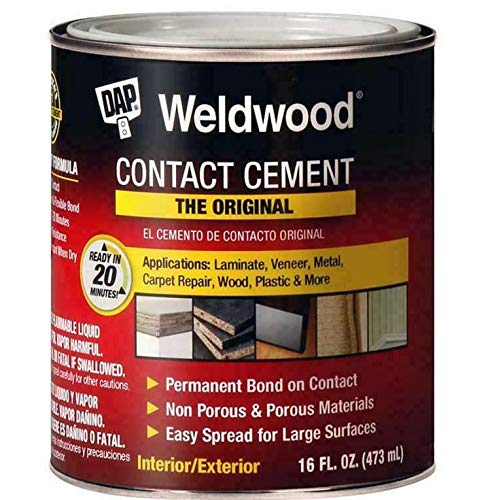

DAP weld wood original contact cement premium quality, neoprene-based contact cement that meets the stringent requirements of the professional userHigh strength and initial grab make it ideal for most projectsThe upc of the product is 070798002715Solvent base formulaQuick grab with super strength with flash point 22° F5 cycle freeze thaw cycle30-45 minute drying time needed for bonding at 75° F and 50% relative humidityThis item is not for sale in Catalina IslandUse on wood, rubber, paper, leather; hundred of items.Recommended for applying plastic laminates, such as Micarta, to counter-tops.Resists water and most chemicals.

Used to do this professionally.

Foam: https://www.thefoamfactory.com/seatcushion/foamtypes.html

You want to use closed cell foam, if possible. Open cell foam can absorb water and fluids(yick).

Temporary Adhesive: 3m77 is the best overall adhesive to prevent movement. It is NOT a permanent adhesive. https://www.amazon.com/3M-77-Multipurpose-Adhesive-Aerosol/dp/B0000AZ735/ref=sr_1_3

Permanent adhesive: Barge cement or weldwood. Both are equally good. Many brands advertise different names, but it's repackaged barge or weldwood (you can get a 55 gal drum). It tends to be more rigid so its only suitable for adhesing to a solid base, like foam to wood or foam to metal. https://www.amazon.com/00271-Weldwood-Original-Contact-Cement/dp/B0006MXRY8/ref=pd_lpo_vtph_200_lp_t_3

Upholstery leather: While Tandy is the cheapest source, they generally sell second quality hides that are factory overruns or seconds. A better source is either the Carroll Leather company or the Hide House. Both are excellent. You want a fully protected corrected grain hide in the 3-4 oz range. The hide should be a full hide, not half, which is approximately 55 sqft. Both companies will sell you a single hide. Estimate about $8 sqft, including shipping. My preference is the Carroll Leather company because they have a better online catalog, but both companies will send you samples if you ask nicely. Both are excellent reputable companies. http://www.carrollleather.com/colours

and https://hidehouse.com/products/index.html?Category=FETI

Also, if you plan to stuff any enclosed leather items, like pillows, you will need spray silicone to ease the stuffing. http://www.upholsterysupplyonline.com/products/Pro-Slip-Dry-Silicone-Spray-Case-Of-12.html

You might need some upholstery tacks and a tack hammer. https://www.vandykes.com/upholstery-tacks-nails-tools/c/1696/

Alternatively a good staple gun works well. Do not use the electric ones. They're expensive and usually don't work as well as the manual ones https://www.amazon.com/Arrow-Fastener-T50-Heavy-Staple/dp/B00002ND61/ref=sr_1_4

For random hardware, try https://ohiotravelbag.com/ and https://www.buckleguy.com/The company behind buckleguy makes the hardware for Coach bags, so it is usually superior quality.

If you sew anything, use polyester thread, NOT nylon. Nylon absorbs water, and breaks down under exposure to UV. Polyester is what the boat upholstery guys use because it stands up over time.

Pro tip: expect to use twice as much leather as you think. It takes a lot of experience to correctly judge upholstery dimensions and usage. Also, pull the leather tighter than you think. Go slow, measure twice, cut once, and realize that leather stretches in two directions.

Edit: Marine vinyl is a good substitution for leather. It's non porous, and easily cleaned. Fabric is measured by the yard, which means the width of the roll (usually 54") x 1 yard long. Quality vinyl is ~$10-$20 per yard, which is about 1/4 the cost of quality leather. https://www.joann.com/marine-vinyl/prd23669.html or https://fabricwarehouse.com/discount-marine-vinyl-fabrics/

borrowing weapons would probably be your best bet for your first event. Get to know what you like fighting with before you waste money & time creating your own.

BUT if you want to create your own, because come on...it's just fun, then head to goodwill. Grab a few GRAPHITE core golf clubs (no metal ones! they bend stupid easy) so grab some golf clubs, head to wal mart and get a few rolls of blue camping foam (with no bumps or ridges on it, just smooth ozark blue foam). Grab a can or two of DAP along with some razor blades and athletic tape. Get some black pantie hoses for your cover and maybe some of those marine foamy seats you get when you go to athletic events and don't want your butt to hurt from those metal bleachers.

Anyways....to make the weapon look for good (NEW) tutorials on YOUTUBE or wherever. I looked for a few min and didn't find anything too useful (I'm also at work, so can't look too much on the tubes of you)

If you want more details, I can do more researching when I get home and edit this post with more videos or tutorials of any sort.

REGARDLESS:: I HIGHLY recommend you get with someone who has made good, passable (!!) weapons so they can help you through the process. You'll make mistakes, realize that, but you'll get better at making weapons.

Good luck and welcome to your new obsession for the rest of your life. :]

If you have access to a laser cutter, you might be able to get it done locally (assuming you can source the leather). It's smelly and will leave slightly darkened edges (I recommend using masking tape all over the side that's being cut, to protect the leather from charring), but it's fast and precise. Alternately, if you have patience, using an X-Acto knife will do the job just fine on thin leather.

I got the applique laser-cut from chevre (goat leather) for these shoes I made, to give you an idea of what's possible: https://www.dropbox.com/s/t8x3w4dwrpz7fdq/2018-01-19%2013.18.51.jpg?dl=0

If you plan to glue them to your existing leather boots, here's some tips:

I don't think so. This is the stuff, but you don't need such a large can of it.

It might be easier to buy not online because it contains solvents that may be subject to shipping restrictions.

You're looking for a rubber cement--essentially, liquified rubber suspended in a stinky solvent. You apply it to both surfaces, wait 10 minutes or so for the solvent to evaporate. At that point, the rubber remaining on the surfaces sticks like hell to itself, so you can put the surfaces together and get a nearly instant bond.